Inside the Baltoro®: Xerox Inkjet Heads Make All the Difference

In 2019, Xerox debuted another industry first: the Baltoro HF Inkjet Press. Half the size of other presses, the Baltoro offers true HD 1200x1200 dpi print resolution and prints on a range of media with no primers and precoats. At the center of this first-of-its-kind press is the Baltoro’s High Fusion (HF) W-Series Inkjet Heads.

Here our head of printhead research and development, Chad Slenes, discusses how Xerox’s heads differentiate the Baltoro.

How do the HF W-Series Inkjet Heads bring new capabilities to the inkjet market?

First, our printheads contribute to what is now the broadest media flexibility in the entry-level, cut-sheet, production inkjet market. The printhead’s small drop sizes also help enable direct printing onto a range of media with high-definition image quality and colour without any primers or pre-coats. This means no fifth liquid is required, reducing the size of the press, its power consumption and total cost of ownership. Finally, we believe this printhead offers unmatched reliability.

How do these heads offer unmatched reliability?

We have more than 25 years of reliability metrics and testing under our belts. Our robust testing process includes running four sets of long-term tests and quick-level tests that are done in a manufacturing setting. These tests check for various elements such as longevity, thermal cycles and conditions and fluidity. With our W-Series testing, we’ve successfully passed 500 billion cycles on 10 printheads and have run more than 100,000 liters through a single printhead. These tests are done over a five-year period, so we know how the printhead will behave and help ensure it meets Xerox’s strict quality standards throughout its lifecycle.

You discussed having 25 years of reliability metrics. How long has Xerox been engineering inkjet heads?

Some are surprised to learn that Xerox has been developing inkjet printheads since 1986.

Tell us about the engineering team behind these innovative printheads.

Many of our engineers have been with us since 1986, demonstrating our deep subject expertise in this area. Today we have more than 250 subject matter experts engineering and manufacturing our printheads at our center in Wilsonville, Oregon. Over the years, this team has helped build and ship more than 2.5 million printheads!

Xerox® High Fusion Ink

Take the cost out of print manufacturing. Extend inkjet benefits to offset coated stocks.

Xerox® High Fusion W-Series Printhead

The future of inkjet. Powered by Xerox.

Related Articles

Xerox Iridesse Virtual Designer Training

Add popular digital Beyond CMYK embellishments to your projects when using the Xerox Iridesse Press.

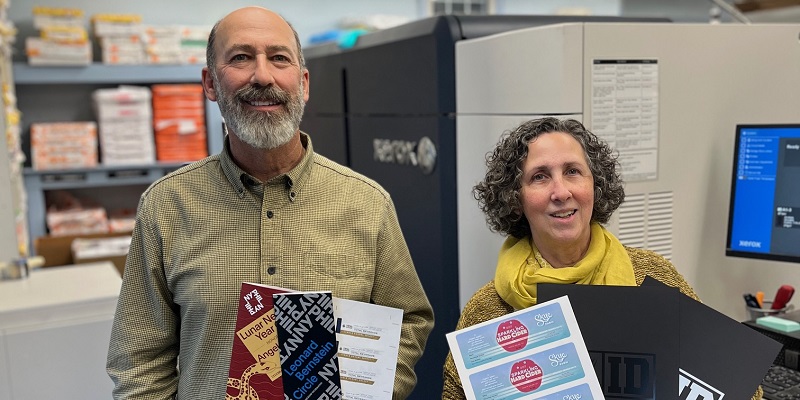

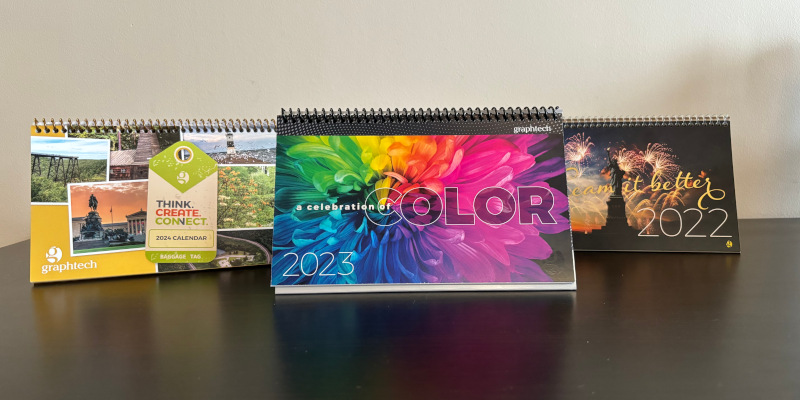

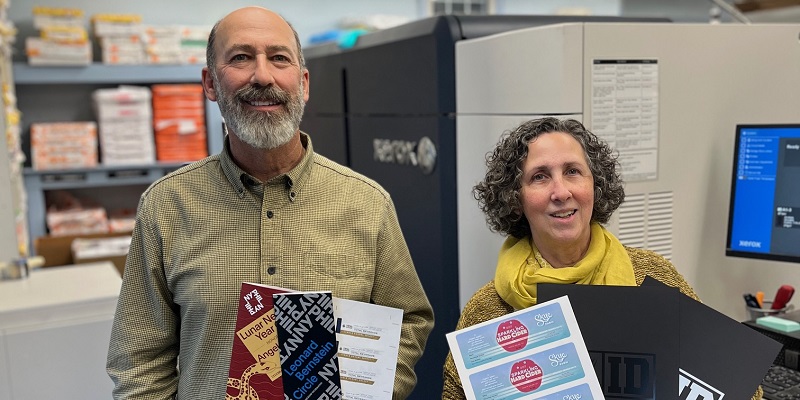

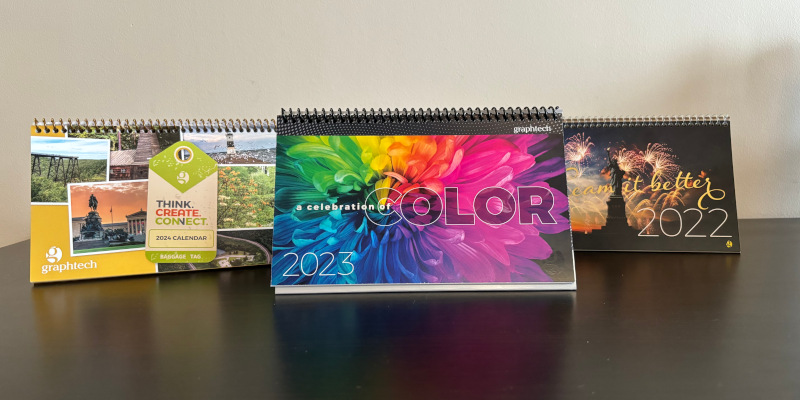

Rapid Press and Xerox: Building Success Together for over 30 Years

Discover how Rapid Press enhanced client satisfaction and productivity with the Xerox® Iridesse® Production Press and gold speciality toner, delivering high-quality, consistent prints that exceed expectations.

Xerox® Iridesse® Presses: Empowering Clients with On-Demand Printing

See how Xerox® Iridesse® Presses helped a client meet complex client needs with on-demand printing, exact quantities, and specialty embellishments, all while maintaining high standards.

40 Years Strong: Pronto Reproductions and Xerox Forge a Resilient Partnership in a Shifting Market

See how the partnership between Pronto Reproductions and Xerox continues to drive agility and growth in a shifting market with the Xerox® Iridesse® Production Press.

UK printer delivers high-value projects while lowering environmental impact

Rapidity gains efficiency, versatility with Xerox® Iridesse® Presses

Unlocking Profits with Digital Embellishments

Get ready to dazzle your clients and boost your bottom line with this power training session from Xerox and Taktiful. Learn strategies to become more profitable marketing, pricing and selling Beyond CMYK applications.