How Choosing the "Right" Print Jobs Can Maximize Profit Margins

By Matthew Parker

Do you know the true cost of running a job?

Naturally, there are some very obvious costs — equipment, materials, machine time, etc. But how do you measure lost profits from running non-standard jobs? Or from inefficient customers?

As pricing becomes an area of greater interest and scrutiny, so does the importance of making sure you are producing the right jobs. One way to do this is by choosing the right customers and centering your business on the types of job they need produced. Focusing on a specific target market can make life a lot easier for your production department and help you build much more profitable relationships.

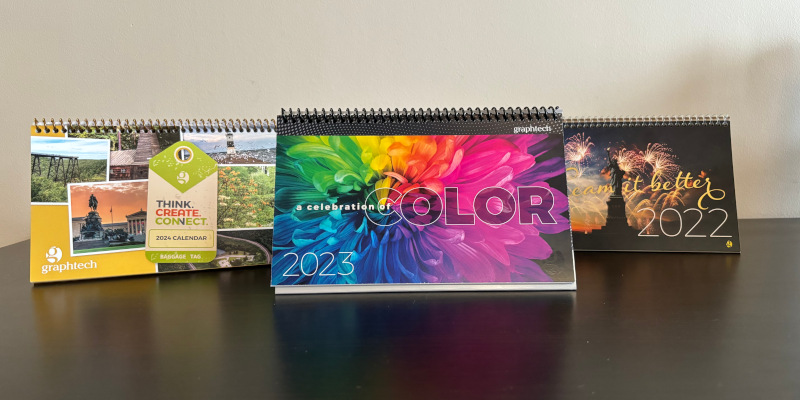

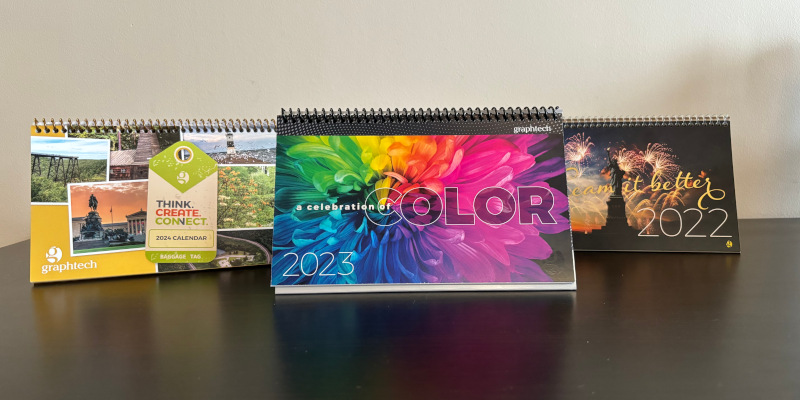

Another is to make sure that you are producing the sort of jobs that suit both your equipment and your company culture. Companies that specialize in magazines, for instance, are well suited to handle the rapid changeover times to produce general commercial print efficiently. Whereas companies that specialize in direct mail have the right variable data and design software in place to efficiently handle that work.

Many print shops simply try to “fill the presses.” The problem is that this leads to your clients dictating the work that fills your facility. If you aren’t careful, it can also lead to commodity pricing. Profit margins can be severely reduced in trying to win jobs that are not really suitable for your business.

How to Decide Which Jobs Are Right for You

Your first step is to review what your best clients require. Ask yourself: is your facility set up to produce these jobs efficiently? Can you remain profitable despite avoiding the types of work that gets in the way of your ideal jobs?

The next step is to sit down and decide what type of jobs you do really well. Does your company excel at highly custom pieces of print that require a lot of intervention? Or do you work best at standard items? Which of your offline finishing processes are most, and least, efficient?

Naturally, the production team should be involved in this process. However, it’s important to think of profit margins and not just ease of production.

At the end of this exercise you may also wish to review whether you are still focusing on the right type of customer. It may be necessary to go through the process of choosing a new target audience after uncovering some production pains and inefficiencies.

Finally, there is one more important job to carry out.

Make Sure You Brief Your Sales Team

Many sales teams aren’t given sufficient guidance on what to sell. So it’s important that yours understands that they are being tasked with winning specific types of work. You may even consider changing levels of commission according to suitability of the job. It will make their work easier if you produce some profile sheets that detail exactly the sort of jobs you wish to focus on.

Start Building a Network of Suppliers

Sometimes, a salesperson will come up with an opportunity that’s too good to pass up, but it doesn’t ideally match your production capabilities. What then?

It is always dangerous to turn away a job from a willing customer. They may end up taking, and leaving, their business in the hands of a competitor. Therefore, it is worth considering partnerships with other printing companies that specialize in different types of work. If you create a small network of suppliers, you will all be able to help each other.

Achieving the Right Results for Your Company

Specialization is never easy. It can feel like you’re passing up on opportunities. And in a world where print runs are under tremendous pressure, that’s definitely a challenge.

But by sticking to the jobs your print shop is made for — and by choosing the right customers — you can build more profitable relationships, work more efficiently and stop worrying about whether or not you’re “filling the presses.”

If you’d like to learn more about which jobs are right for your organization, drop us a line. We’d be happy to help. To stay informed on the latest production printing trends and news, don’t forget to subscribe.

Related Articles

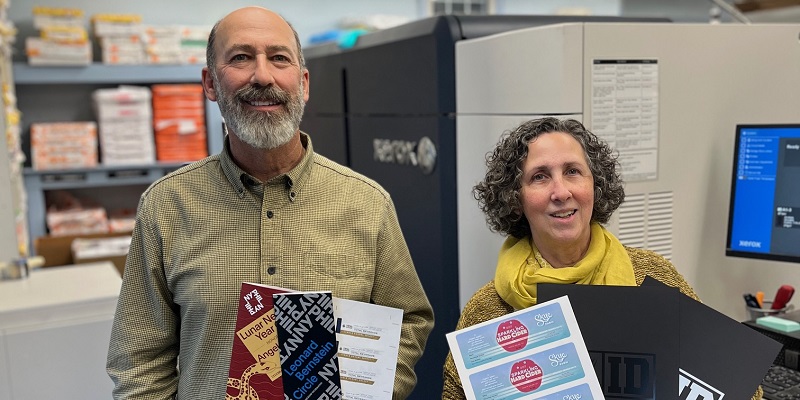

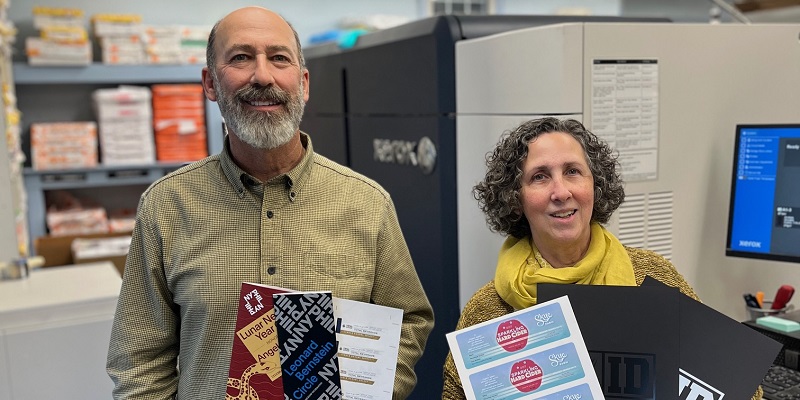

40 Years Strong: Pronto Reproductions and Xerox Forge a Resilient Partnership in a Shifting Market

See how the partnership between Pronto Reproductions and Xerox continues to drive agility and growth in a shifting market with the Xerox® Iridesse® Production Press.

Xerox® Iridesse® Presses: Empowering Clients with On-Demand Printing

See how Xerox® Iridesse® Presses helped a client meet complex client needs with on-demand printing, exact quantities, and specialty embellishments, all while maintaining high standards.

Xerox Iridesse Virtual Designer Training

Add popular digital Beyond CMYK embellishments to your projects when using the Xerox Iridesse Press.

Virtual Designer Training: Xerox Adaptive CMYK+ Kit

Use popular digital embellishment techniques in your designs with adaptive CMYK+ kits on the Xerox Versant and Xerox PrimeLink Production Press

UK printer delivers high-value projects while lowering environmental impact

Rapidity gains efficiency, versatility with Xerox® Iridesse® Presses

Rapid Press and Xerox: Building Success Together for over 30 Years

Discover how Rapid Press enhanced client satisfaction and productivity with the Xerox® Iridesse® Production Press and gold speciality toner, delivering high-quality, consistent prints that exceed expectations.