Xerox® Automated Packaging Solution for the Xerox® iGen® Press Product Family

Now commercial printers and converters can satisfy brand owners’ growing demands for short-run versioning with our entry-level, inline, digital print packaging solution.

Capabilties

Key Features

Key Features

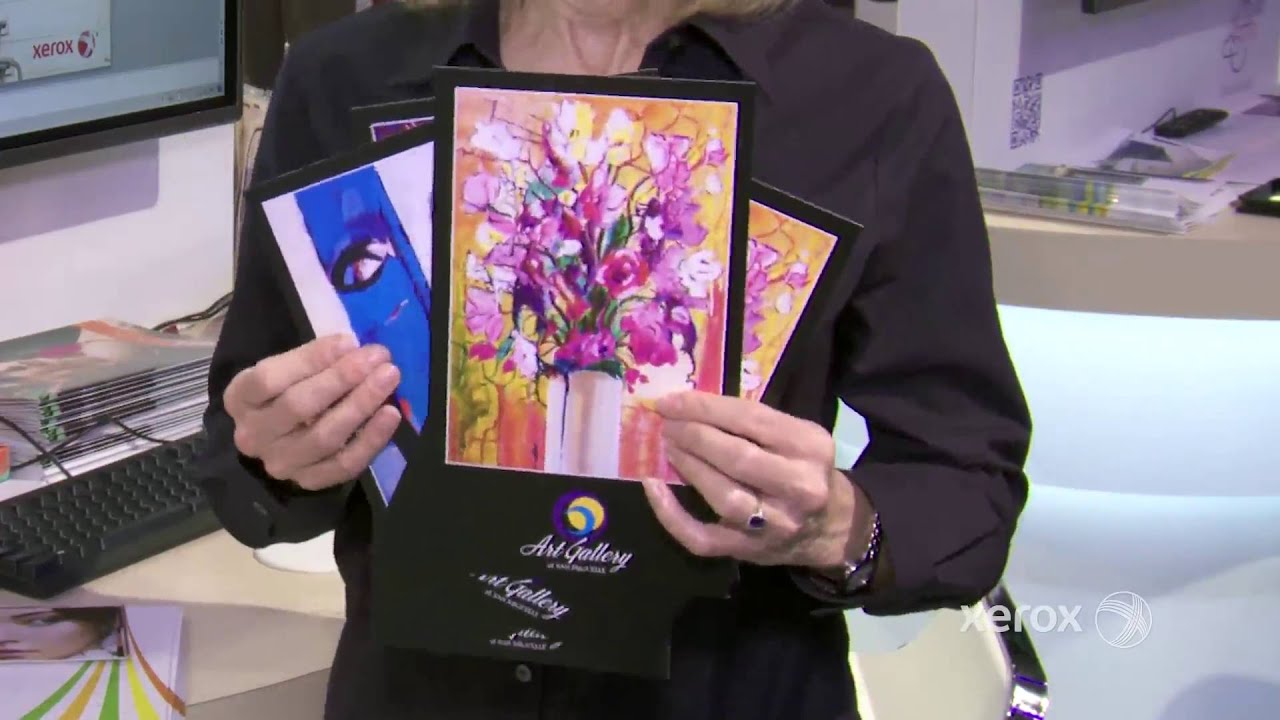

Helps brand owners overcome today's challenges. Accommodate your customers’ needs for multiple languages, SKUs, regional preferences or targeted marketing by changing messaging, colors and images on the fly.

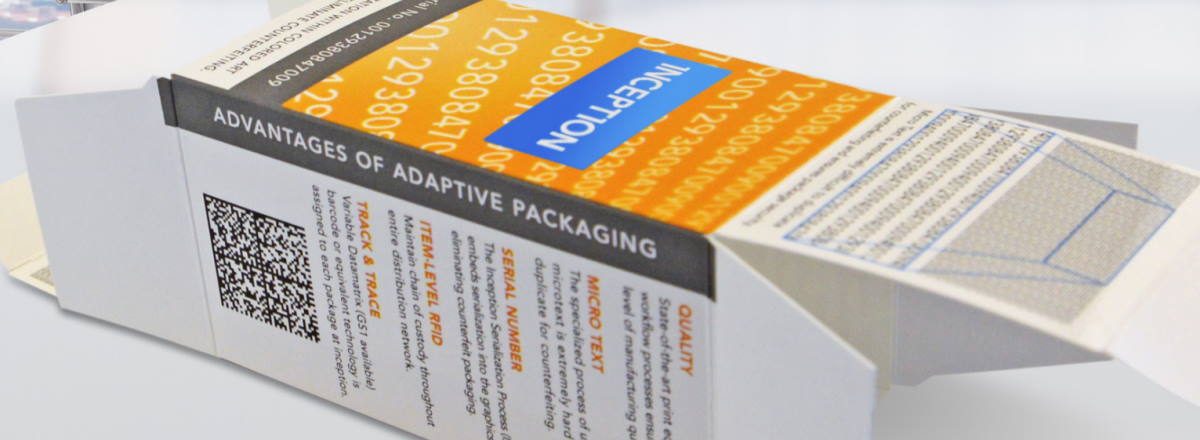

Satisfies demand for brand protection. Enable item-level product identification for tracking and tracing, as well as advanced counterfeiting measures.

Achieves brand-critical colors with ease. Reproduce up to 90% of the Pantone® Plus Coated library within 3 Delta E with the Xerox® iGen® 5 Press and its optional fifth station (orange, green, blue).

Extends media latitude. For environments where use of high-caliper media is required, an optional Thick Stock Capability extends media range to 24 pt. (530 gsm, 610 microns). Or produce oversize cartons with an optional XLS capability extending sheet size up to 14.33 x 35 inches (660 mm x 889 mm).

Adds "wow" with embellishments. Use the fifth print station to add white for printing on specialty kraft or colored stocks. Or add clear or fluorescent yellow for eye popping designs.

Food Packaging Compliance. The Xerox iGen dry ink formulations are compliant with the Federal Food, Drug, and Cosmetic Act.

Modular architecture. The Xerox Automated Packaging solution is scalable to fit existing workflows. Choose to start with an iGen Press and produce digital packaging or add the versatile coating unit to drive more value with your printing services. Additionally, you can integrate a web store front, printer, coater, and custom die cutter for a complete, end-to-end system.

Digital Printing

Digital Printing

Deliver high-quality, short-run printed packaging that’s fast, effective and affordable with these world-class digital presses:

Job Acquisition and Prepress Workflow

Job Acquisition and Prepress Workflow

Start small or scale large. The Xerox Automated Packaging Solution is designed to fit your existing workflow. Compatible components include:

XMPie® PersonalEffect® StoreFlow™: Automate job acquisition with online tools and cloud resources to let the work flow 24/7.

Xerox® FreeFlow® VI Suite and XMPie® PersonalEffect®: Turn the package into a powerful marketing tool by increasing brand exposure, infusing brand protection and fostering long-term consumer engagement.

Xerox® FreeFlow® Core: Simplify job preparation activities and reduce errors.

Inline or Offline Coating Systems

Inline or Offline Coating Systems

Fast, efficient coaters can run inline or offline, and offer options for UV, aqueous or both. Compatible products include:

TRESU Pinta Coater: Innovative, inline coating solution for digital sheet-fed folding carton production that is 100% modular and designed to perfectly integrate with the Xerox® iGen® series of presses.

Actega (Coating Fluid): State of the art topcoats options, such as Goss, UV, Matte, Aqueous Pearlescent and SoftTouch, and primer solutions.

Inline or Offline Die-Cutting Systems

Inline or Offline Die-Cutting Systems

State-of-the-art digital die cutting solutions, ensuring every job is precise and ultra-efficient. Compatible products include:

KAMA DC76: Provides die-cutting, creasing, perforating, brail embossing, foil stamping, relief embossing, and holograms for short runs with added value finishing.

Highcon Euclid (offline only): The world’s first production-speed digital cutting and creasing machine. It transforms cutting and creasing from an analog to a digital workflow, dramatically streamlining the finishing process.

Offline Digital Coating and Decoration

Offline Digital Coating and Decoration

Enrich your digital output with unique coatings and effects for appeal and differentiation. Compatible products include:

Scodix Ultra Pro™ Digital Enhancement Press: Provides unique, eye-catching coatings and effects on a wide variety of stocks, adding tremendous value to printed applications.

Duplo Digital Spot UV Coater DDC-810: Add print embellishments with spot coating, texture and tactile effects

Skandacor Protopic 540: Fuser single sided laminator / sleeker

Xerox® Automated Packaging Solution

The first integrated, inline digital solution for folding carton packaging.

Xerox® BrandSecure Packaging Solution

Affordably produce serialized folding cartons, complete with anti-counterfeiting measures and tracking.

Case Study: OTC Group Drives Solution for Pharma Packaging

Xerox drives serialization solution for pharmaceutical packaging.

Thick Stock Capability for iGen 5

Thick Stock on the iGen 5 presses supports heavier, high-bulk substrates and carton-board for packaging and signage applications - up to 24 point or 610 micron.