Rapid Press and Xerox: Building Success Together for over 30 Years

“From corporate giants to boutique clients to printers, at Rapid Press, we deliver consistent, high-quality printing with innovative speciality dry inks, making us a trusted partner in the industry."

About the Client

Rapid Press, established in 1979, has evolved from a small family-owned print shop into a reputable powerhouse print provider with a mighty team of six people serving designers, local businesses, major brands, and corporate clients across Stamford and Norwalk Connecticut, and the New York metropolitan area.

With backgrounds rooted in diverse fields, Co-Owners Bill Fishman has a background in Mechanical Engineering and Hilary Huaman with a background as a Biologist brings a mix of engineering and artistic expertise to the business. Rapid Press operates a storefront in Stamford, but the bulk of their work comes from larger, corporate accounts, pickup, delivery, and various electronic interactions from many other smaller clients. Their print manufacturing primarily revolves around a single, reliable, and robust six-colour Xerox® Iridesse® Production Press, a cornerstone for maintaining high-quality and versatile printing options, essential to their business success for the past several years. Key applications include booklets and brochures (either of these can be full bleed and or very heavy coverage), business cards, NCR Forms, and the list goes on.

“We needed to overcome bottlenecks with a reliable, high-quality print solution.”

The Challenge

Solving Downtime, Quality, and Client Retention with Iridesse Press

Before implementing the Xerox® Iridesse® Production Press, Rapid Press faced several notable challenges. The first was attracting and retaining clients second was dealing with production bottlenecks and frequent downtime. When their previous machine needed repairs, it often resulted in significant delays, negatively impacting productivity and client satisfaction. The limited capability of their former equipment restricted their ability to offer alternative media finishes and speciality inks, making it difficult to compete with the high-quality standards expected by their clients in competitive markets. Additionally, they needed reliable colour consistency for client reprints, a feature their previous machines could not fully support. Hilary Huaman added, “Our goal was to achieve offset-quality results, and the Iridesse's 10-bit colour capabilities delivered exactly what we needed. This advanced technology allows us to produce stunning, high-definition prints that meet the highest standards—empowering us to exceed client expectations with every project."

“The Xerox Iridesse Press is the heart of our business.”

The Solution

Rapid Press Boosts Creativity with Iridesse Speciality Inks

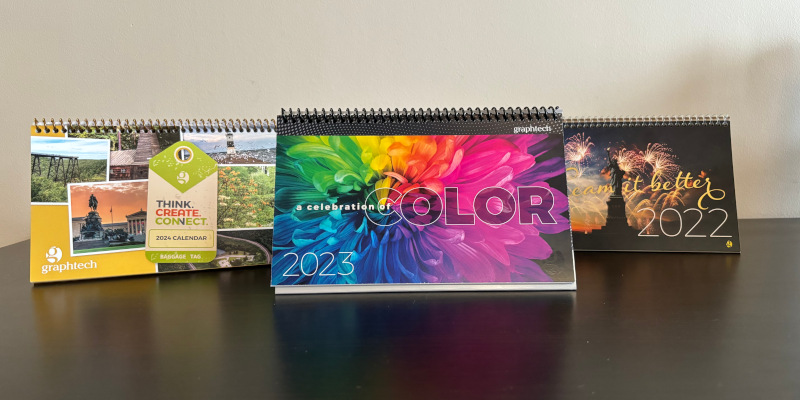

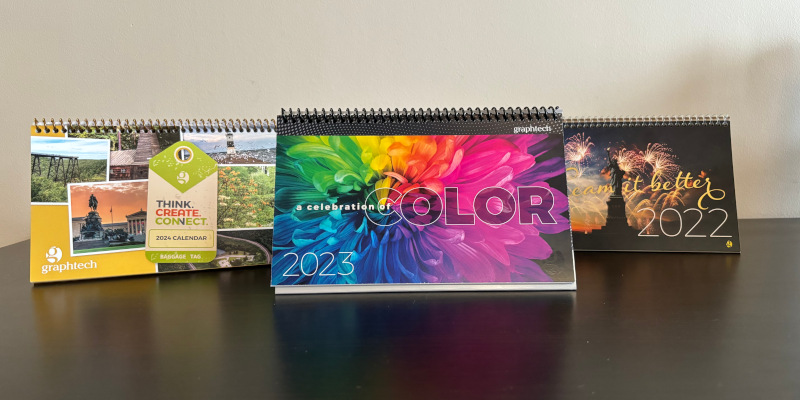

To address these issues, Rapid Press invested in the Xerox® Iridesse® Production Press, equipped with speciality dry inks (SDIs) that included Gold, Silver, White, and Clear, as well as taking full advantage of its built-in automated features to achieve colour consistency and registration. This press improved reliability and introduced new possibilities for creative and high-quality printing, meeting the standards needed for corporate and creative clientele alike. Rapid Press has also marketed this capability to other printers, broadening its client base and introducing designers to the creative potential of the Xerox® Iridesse® Production Press speciality inks, which offer an affordable alternative to traditional foil stamping. According to Bill Fishman, "We collaborate with several high-end luxury brands and other local printers to elevate their print designs, and our use of gold toner creates a truly striking, premium effect that these brands crave. Unlike traditional four-colour methods, gold toner delivers an unmatched level of brilliance and sophistication, capturing attention instantly and enhancing the luxury appeal they seek."

“The Xerox Iridesse Press in an 8-hour shift can easily work on a dozen different jobs, on a dozen different media with a dozen different requirements, and perform flawlessly.”

The Results

Enhancing Reliability, Quality, and Client Engagement with Iridesse Technology at Rapid Press

Improved Operational Reliability and Flexibility: The Xerox® Iridesse® Production Press allowed Rapid Press to avoid production backlogs, even with a single machine, thanks to its reduced downtime and fast recovery when maintenance was required.

Enhanced Print Quality and Consistency: The four-colour process printing on the Xerox® Iridesse® Production Press significantly improved over previous equipment, producing high-quality, offset-comparable results. This reliability in colour accuracy also allowed for better client satisfaction, especially for repeat orders that needed to match prior outputs.

Diversification of Client Base: Rapid Press successfully expanded from a few large clients to a broader base of smaller clients, making the business more stable. This shift also included other print shops using Rapid Press's speciality ink options for unique eye-catching projects.

Speciality Inks as a Differentiator: The addition of speciality dry inks (SDIs) like gold, silver, white, and clear helped Rapid Press attract clients needing high-end custom prints, such as metallic designs. This capability became a unique selling point that set them apart from local competitors.

Positive Industry Perception and Client Engagement: Through seminars and marketing efforts, Rapid Press positioned itself as a high-quality, innovative print provider. These initiatives improved its reputation, especially among designers, and encouraged creative use of its speciality inks.

The Challenge

Difficulty attracting and retaining clients due to frequent production bottlenecks and downtime with previous equipment, leading to delays that affected client satisfaction.

Frequent repairs and interruptions with the former machine created significant productivity challenges, impacted ability to meet client deadlines.

Limited capabilities of previous equipment restricted Rapid Press from offering a range of media finishes and speciality inks, which are necessary to compete with high-quality standards in the market.

Achieving reliable colour consistency for reprints was a recurring challenge, as previous machines could not deliver the offset-quality results that clients demanded for premium projects.

The Solution

Addressed print reliability and consistency issues by investing in the Xerox® Iridesse® Production Press, which offers automated colour and registration controls to maintain high-quality standards.

Speciality Dry Inks (SDI) of the Iridesse® Press (Gold, Silver, White and Clear) enable Rapid Press to expand its creative print capabilities, making it an appealing choice for corporate and creative clients.

Collaboration with luxury brands. The Gold ink creates a brilliance and premium feel that surpasses standard four-colour printing, capturing attention and aligning with the quality expectations of high-end clientele. It’s delivering a sophisticated, eye-catching effect that elevates print materials and brand appeal.

The Results

Improved Operational Reliability and Flexibility. The Xerox® Iridesse® Production Press allowed Rapid Press to avoid production backlogs, even with a single machine, thanks to reduced downtime and fast recovery when maintenance was required.

Enhanced Print Quality and Consistency. The four-colour process printing on the Iridesse® Press significantly improved over previous equipment, producing high-quality, offset-comparable results.

Diversification of Client Base. Rapid Press successfully expanded from a few large clients to a broader base of smaller clients, making the business more stable.

Speciality Inks as a Differentiator. The addition of Speciality Dry Inks (SDI) (Gold, Silver, White, Clear) helped Rapid Press attract clients needing high-end custom prints, such as metallic designs.

Positive Industry Perception and Client Engagement. Through seminars and marketing efforts, Rapid Press positioned itself as a high-quality, innovative print provider.

Découvrez la presse de production Iridesse® de Xerox®

Toners spéciaux Xerox®

Donnez une nouvelle dimension à vos pages et à votre activité.

Articles connexes

Spectrum Print Plus : couleur, clients et engagement

« Après des mois d’évaluation rigoureuse, le gagnant était en face de nous depuis le début, et c’était la presse de production Iridesse ! »

Xerox® Iridesse® Presses: Empowering Clients with On-Demand Printing

See how Xerox® Iridesse® Presses helped a client meet complex client needs with on-demand printing, exact quantities, and specialty embellishments, all while maintaining high standards.

L'imprimerie britannique réussit des projets à forte valeur ajoutée et réduit son impact sur l’environnement

Rapidity progresse à la fois en efficacité et en polyvalence grâce aux presses de production Xerox® Iridesse®.

Virtual Designer Training: Xerox Adaptive CMYK+ Kit

Use popular digital embellishment techniques in your designs with adaptive CMYK+ kits on the Xerox Versant and Xerox PrimeLink Production Press

Solving Print's Pain Points

Explore the latest trends and solutions in print operations with Printweek’s special supplement, sponsored by Xerox. Gain insights into digital transformation, efficiency, and sustainability for your print business.

Unlocking Profits with Digital Embellishments

Get ready to dazzle your clients and boost your bottom line with this power training session from Xerox and Taktiful. Learn strategies to become more profitable marketing, pricing and selling Beyond CMYK applications.