Pricing Beyond CMYK: Printers answer the most asked questions

You’ve seen how specialty enhancements such as metallic, clear, white, gamut extension colors and fluorescent dry inks and toners can transform an ordinary print job into one that stands out and draws attention.

You’ve read that customers are willing to pay a premium of 27% to 89% for print enhancements beyond traditional CMYK.1

And you want to get in on the massive opportunities.

But, if you’re like many print shop owners, you have questions. Here are some answers to the questions we hear most.

1. How much do i sell it for?

"My typical runs are a few hundred pieces. I usually charge about $100 more on each job for setup. I also add up to $1 more per piece for silver or gold ink."

While there is no magical mathematical equation for Beyond CMYK pricing, there are many considerations that factor into the price you can charge. These include the market demand for a type of embellishment, brand recognition of the client and number of local competitors, as well as the type of media, area coverage of the specialty dry ink/toner, method of finishing, degree of personalization and your cost per click.

For Zoltån Kanovits, CEO of Kanovits Print Atelier in Slovakia, the formula comes out to be an average of 3X the total cost of the print. He calculates the cost of the specialty dry ink used based on area coverage for the application. He adds that to the base print cost and factors that, along with a markup, into the final charge.

2. How do I move the conversation with my customers from price to value?

This one is simple: Seeing is believing.

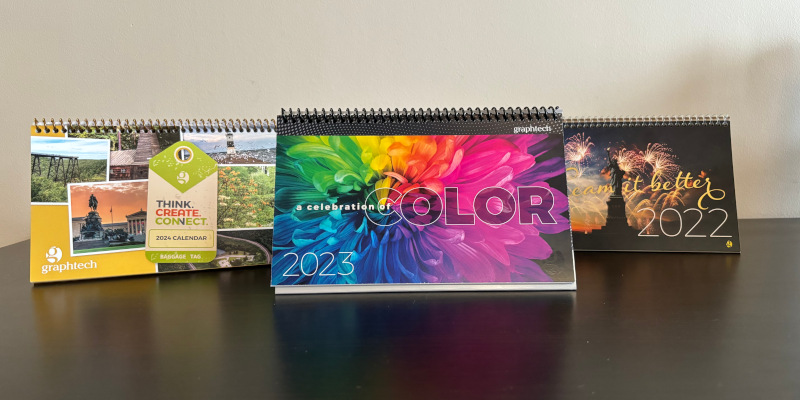

Many print shop owners find that sharing sample kits to put the product in marketers’ hands is all it takes. When you compare the value Beyond CMYK brings to every application in terms of stopping power and the ability to exceed your customers’ expectations and increase their loyalty, it’s no longer a dollar per dollar comparison.

Many said their customers will pay the highest premiums for textures, foils and metallics (40% to 89%), and lower premiums for specialty-spot color and coating (24% to 37%).1

“We consult with our clients about how their artwork could be enhanced with specialty colors. Sometimes we hook them by giving away the enhancement portion of the job for free initially. If you show your customer a beautiful job, they’ll come back for more.”

3. How much will it cost me?

"The dot-coms of the world are competitively priced, but can’t handle walk-ins with same-day turnarounds like I can. Specialty print in a tight time frame commands a premium.”

Specialty dry inks/toners can be more expensive than CMYK only. There are ink and toner usage costs and technology add-ons to consider. Unlike some companies that add a premium click charge for specialty colors, we treat them the same as CMYK. In any case, those costs are minimal when you compare to offline alternative processes such as foil stamping, embossing, spot varnishing, etc. Doing all this inline with CMYK saves time and means no additional labor or equipment.

With short run and personalization capabilities, digital Beyond CMYK effects typically generate additional pages and new print jobs, which drives increased revenue.

4. What’s the ROI?

ROI can be measured in many ways, including new application possibilities, higher print volume, uplift in pricing strategies, improved margins, the ability to provide capabilities that competitors cannot and expanded high-value offerings such as marketing and design services.

One thing is clear, though: Going Beyond CMYK is rapidly becoming an important product differentiator, as well as an enabler for application expansion and more offset page transfer.

All of which translates to a greater return on investment for you because you can charge more for that added value.

“When we price a job, we start by figuring out the CMYK cost per click. When I add specialty dry ink, I increase that click charge by a few cents. I also put a premium on top of that to help pay for the cost of my lease.”

In summary, there is no one-size-fits-all pricing structure for selling Beyond CMYK. It’s an art and science that depends on your market, your operation and your end goals. But trailblazers who have adapted to the future of print are proving the rewards are well worth it. And we’ve prepared a series of guides to take the mystery out of the equation. When you’re ready to go Beyond CMYK with your customers, contact your Xerox rep to continue the conversation. In the meantime, request your free guides to get up to speed on how to develop the pricing structure that’s right for your business.

* Pricing strategies adapted from use cases shared by actual Xerox customers.

1. KeyPoint Intelligence – InfoTrends “Beyond CMYK – The Use of Specialty Inks in Digital Printing”, 2016.

Request Pricing Estimation Guide

Thanks for your interest, A sales representative will contact you soon.

Artigos Relacionados

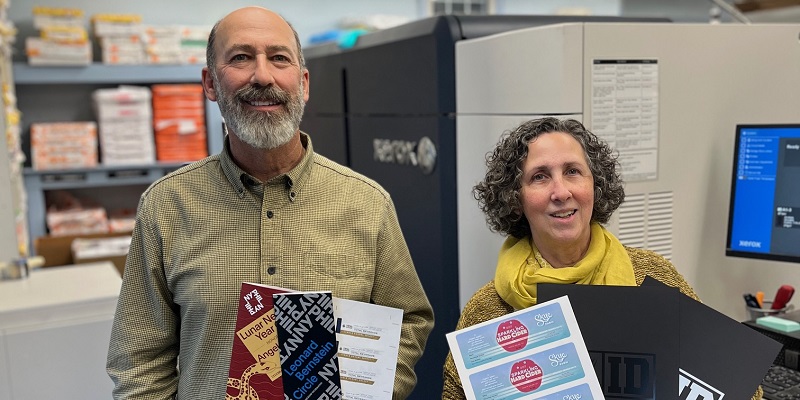

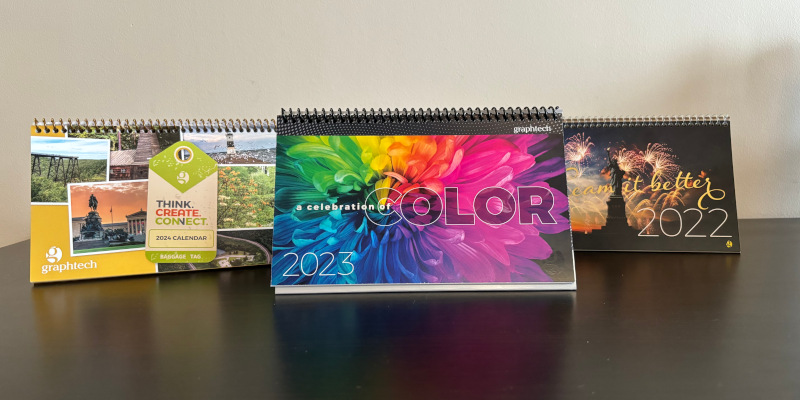

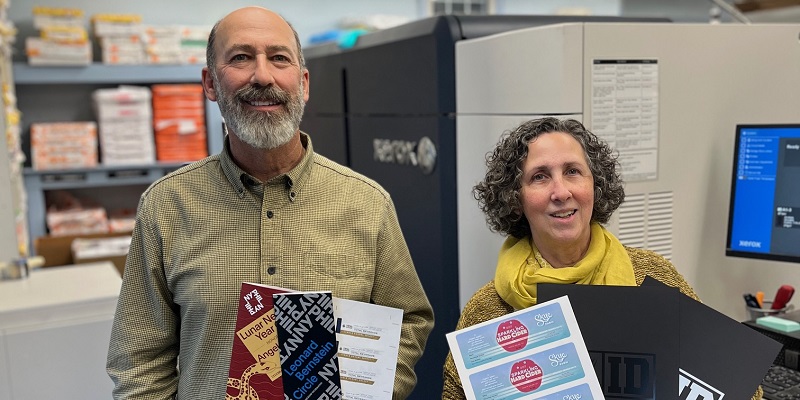

Rapid Press e Xerox: Juntos, construímos o sucesso há mais de 30 anos

A Rapid Press evolui para um fornecedor de impressão poderoso com a Impressora de Produção Xerox® Iridesse®.

Spectrum Print Plus: O negócio de cores, clientes e compromisso

“Após meses de rigorosa avaliação, o vencedor claro esteve sempre à nossa frente — foi a Impressora de Produção Iridesse!”

A gráfica do Reino Unido oferece projetos de alto valor enquanto reduz o impacto ambiental

Rapidity ganha eficiência e versatilidade com as impressoras de produção Xerox® Iridesse®.

Impressora de Produção Xerox® Iridesse®: Capacitando os clientes com impressão sob demanda

Veja como as impressoras Xerox® Iridesse® ajudaram um cliente a atender às necessidades complexas do cliente com impressão sob demanda, quantidades exatas e enfeites especiais, tudo isso mantendo altos padrões.

Xerox Iridesse Virtual Designer Training

Add popular digital Beyond CMYK embellishments to your projects when using the Xerox Iridesse Press.

Virtual Designer Training: Xerox Adaptive CMYK+ Kit

Use popular digital embellishment techniques in your designs with adaptive CMYK+ kits on the Xerox Versant and Xerox PrimeLink Production Press