Pioneering a Circular Economy

Central to our journey toward waste-free workplaces is the drive toward a circular economy.

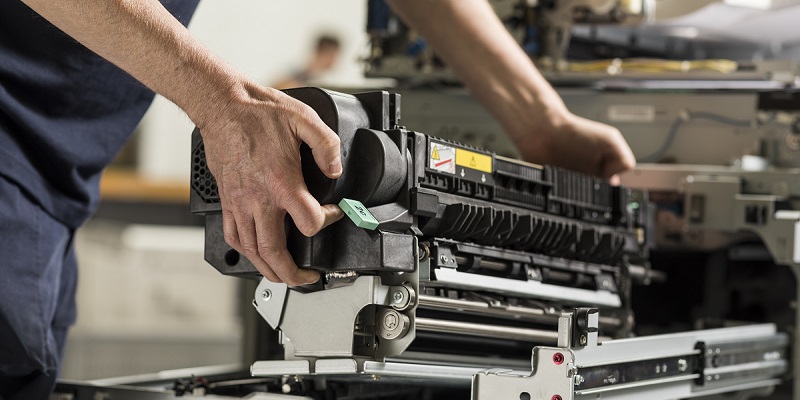

At Xerox, we believe that reducing waste is not only good for the environment, but also for your business. That’s why we pioneered this practice decades ago, by remanufacturing, refurbishing and recycling office equipment. Our devices are built to last, with fewer parts, easy disassembly, and strict chemical standards. We want you to enjoy high-quality performance while helping you reduce your environmental impact.

A longstanding commitment to waste-reduction

We have embedded circularity in our products since 1959, long before the term circular economy was created, and take a life cycle approach to low carbon design, addressing impacts from raw materials and manufacturing, transportation, use and maintenance, through extended life management.

With the rise of regulations on resource use and stakeholder sensitivity to waste management and environmental impacts, more consumers and organizations now prioritize circularity in their purchasing decisions and brand perception.

Supporting our clients' circularity needs

Our vision for circularity extends to our clients’ workplaces, where electronics and supplies at the end of their useful life can come full circle to become the raw materials of tomorrow. Where, without compromise to product quality and the client experience, natural resources are conserved, and waste becomes obsolete.

To achieve this vision, we incorporate a comprehensive Design for Sustainability approach, covering four key phases of a circular economy:

Design

The careful selection of raw materials, considering reuse, recycled content, and safety, as well as ecolabel criteria and product life cycle impacts.

Manufacturing

Equipment and supplies reuse, remanufacturing, and employment of an environmental management system in operations are aligned with the production phase.

Consumption

Includes best practices such as energy efficiency, more responsible printing, data visibility to drive improvements, carbon offsetting, remote repair and maintenance.

Extended Life

Our global collection, reuse and recycling programs enable extended life management for equipment and supply items, giving them a second life and reducing the use of new materials.

Preventing and Managing Waste

We are committed to producing waste-free products in waste-free facilities to help our clients reduce waste. Our aim is to design products, packaging and supplies that make efficient use of resources, minimize waste, reuse material where feasible (including recycled plastics), and recycle what can't be reused.

At Xerox, we not only remanufacture, reuse and recycle equipment, but we expect the same commitment to sustainability from our suppliers. This way, we can reduce our environmental impact together. Packaging waste is also being reduced by removing single use plastics and increasing recycled content.

We also make it easy to repair and maintain your Xerox products. If you buy a new Xerox product, you can rest assured that you will have access to spare parts.* This means you can keep your Xerox products running smoothly and efficiently for longer, while reducing waste and saving money.

Globally, our returns programs for equipment resale and remanufacture in conjunction with parts recycling prevented 27,999 metric tons of waste from entering landfills in 2022. 4.3 million consumables were also returned in 2022 from the 35 countries participating in the Xerox Supplies Recycling Program, enabling 1.6 million Xerox toners to be manufactured using recovered cartridges.

As much as 52% post-consumer recycled plastic is included in our latest desktop office printers, and we reuse as much as 95% of reclaimed parts in larger devices.

See our latest performance figures in our corporate social responsibility report, goals, and progress summary

*Blue Angel and products in the scope of the EU Ecodesign Framework standards have access to select spare parts for seven years

Explore services and operations that are helping to reduce environmental impacts

Xerox Supplies Recycling Program

Millions of cartridges and toner containers are returned for reuse or recycling each year through the Xerox Supplies Recycling Program.

Xerox Reverse Logistics

Since 2009, Xerox has diverted more than 590 thousand metric tons of returned equipment, parts, and supplies from landfill by remanufacturing, reusing, or recycling.

Waste-free Factories

Since the 1990s, our Waste-Free Factory initiative has employed an ISO 14001-compliant environmental management system to help achieve a 93% recycling rate for non-hazardous materials.

Sources:

2. Deloitte The Sustainable Consumer 2023

4. United States Environmental Protection Agency Greenhouse Gas Equivalencies Calculator | US EPA

Environment, Health, Safety, and Sustainability at Xerox

Sustainability in business has never been more important. Explore Xerox solutions for more sustainable printing, reduced environmental waste and more EHS efforts.