Sustainable Services and Products

We consider environmental priorities in the design of our products and services; it’s better for our customers, our business and the environment. We solicit feedback from clients and other stakeholders and take a forward-looking view of global trends in technology, regulations and eco-labels. We’ve developed a comprehensive sustainability program based on global standards and quantitative analysis.

Samples of our work:

- Charter partner of the U.S. Environmental Protection Agency (EPA) ENERGY STAR® program; 100 percent of all new eligible Xerox product introductions meet ENERGY STAR® 2.0 requirements for Imaging Equipment.

- Since the inception of IEEE 1680.2 Imaging Equipment Standard (EPEAT®) in 2013, Xerox has registered all newly launched office products to this set of performance criteria. We have a 100 percent compliance rate for EPEAT® audits.

- Through a partnership since 2006 with the Nature Conservancy, The Xerox Foundation grants of more than $2 million have helped preserve and protect globally important forests.

Reducing Environmental Impact through Our Services and Solutions

Our expanding Managed Print Services business in combination with our extensive print fleet offers solutions that reduce energy consumption and improve environmental performance.

Our equipment and software is designed to help customers operate efficiently. The “earth smart” feature, integrated into the Xerox global print driver, brings several resource-saving settings together at the single click of a button. These features, such as duplex (two-sided printing), n-up (multiple pages per sheet), proof print and toner saving modes, make it easier for customers to make responsible print choices. Our Xerox Enterprise Print Services customers have access to sophisticated print management and reporting tools, such as Xerox Print Agent, which provides additional methods of encouraging and tracking responsible print behaviour. Software products such as DocuShare® and FreeFlow® Digital Workflow Collection help Xerox customers reduce paper consumption by facilitating electronic data management, scan to email, print-on-demand and distribute-then-print workflows.

Xerox has also been exploring creative ways to engage employees in the sustainability effort. The Xerox® Print Awareness Tool is a unique managed print service approach to sustainability management and reducing print volumes. By using this tool, users can see their print usage, using an easy, interactive desk interface, and take steps to improve print behaviour. Through each user's contribution to improvement, customers get one step closer to decreasing overall print costs and achieving corporate social responsibility and sustainability goals. In 2014 Xerox launched CompleteView™ Pro, another tool in the managed print assessment process that, in part, provides customers with a sustainability analysis documenting the environmental impact of print output such as power consumption and CO2 emissions by device and site. Learn more at managed print services.

Using the full suite of Managed Print Service tools, we work with customers to improve the efficiency of office document management by assessing printing needs and developing solutions. Using this approach, customers can better achieve these goals:

- Energy and Greenhouse Gas reduction: Print asset optimization and updates improve energy consumption, reduce Greenhouse Gas impact, and reduce waste materials.

- Reduced paper usage: Using both print authentication and authorization, along with gamification techniques, print behaviors can be changed to reduce unnecessary prints.

- Reduce waste: Newer, more sustainability print technologies and consumables drastically reduce the amount of waste generated from printing practices.

- Digital Transformation: Other paper reductions comes from adoption of digital workflows integrated with Enterprise Content Management (ECM), digital alternatives.

In addition, we use a comprehensive design for the environment approach when designing and developing our products so that environmental impacts are minimized throughout the supply chain.

Learn more about how we design for the environment. +

Standards

Our product standards encompass the following: energy efficiency, chemical management, packaging, parts reuse and recycling, electrical and mechanical safety, ergonomics, electromagnetic emissions, noise, fire resistance and materials safety. Xerox business teams and our Environmental Health, Safety & Sustainability (EHS&S) organization review our products at each stage of the development process for conformance with environmental, health and safety standards, which is a requirement for the introduction of any product. All Xerox standards ensure our products have the appropriate labels and information needed to meet all safety and environmental label requirements to keep our customers appropriately informed. All products meet required industry labeling standards for each market.

Lifecycle Assessment

Xerox integrates lifecycle thinking into all of our product and service development activities as well as our innovation activities. Lifecycle Assessments (LCAs) are a means of technically evaluating the environmental impact of a product’s materials, manufacturing, distribution, use and end-of-life. We conduct full LCAs — in accordance with the appropriate ISO standards — to determine where in the product lifecycle the largest environmental impacts arise and to compare products with a significant difference in technology. Full peer-reviewed LCAs have been performed on our solid ink products (8860, 8870, 8700 and ColorQube 9200 series) and many of our laser technology devices (WorkCentre 5325/30/35, WorkCentre 5945/55, and Phaser 7100). Many of these LCAs directly contributed to our achieving the Electronic Products Environmental Assessment Tool® (EPEAT®) Gold certification for these configurations and provided valuable input to our design teams to determine future opportunities for reductions in environmental impacts. We encourage our customers to learn more about how their printing behavior affects the overall carbon footprint of their organization from a lifecycle perspective.

Product Design

Xerox has long incorporated environmental considerations into product design. Internal processes ensure that product design teams are informed about regulatory and market driven changes affected by product design. These processes ensure that product design teams are able to incorporate timely environmental and product safety considerations. Scientists in our materials research group evaluate aspects of Safety, Energy, Materials and Sustainability (SEMS) using a tool we developed that enables researchers to quickly compare the current design with a future proposed design. The tool challenges designers to think about the whole lifecycle of the product and recognize any positive or negative impacts to the environment. By using SEMS, we can quantify energy reductions, reduce risk of regulated materials and track progress over time. SEMS was designed to be used in early research and development stages to understand tradeoffs and help make decisions.

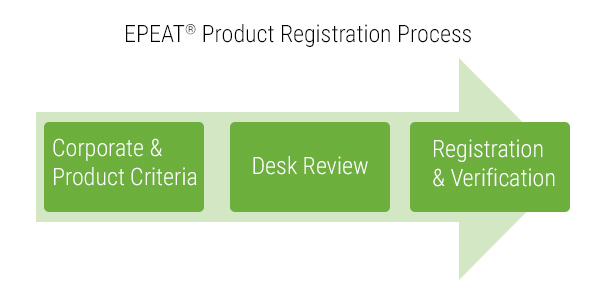

EPEAT®

For office products, Xerox uses EPEAT® as the foundation of our Design for Environment program. A comprehensive environmental rating system, EPEAT® identifies electronic equipment that meets specific criteria. The diagram below shows the rigor of the system. EPEAT® is composed of criteria spanning corporate and product requirements (50+ requirements for imaging equipment). When a company and product meets these criteria, it must pass a third party desk review. Only after a satisfactory review, the product can be registered and verified annually to ensure compliance.

EPEAT® combines comprehensive criteria for design, production, energy use and recycling with ongoing independent verification of manufacturer claims. EPEAT® criteria reflect several categories of environmental attributes that span the lifecycle of electronic products: material selection, design for end-of-life, product longevity/life extension, energy conservation, end-of-life management, corporate performance, packaging, consumables and indoor air quality. Xerox continues to support EPEAT® initiatives and has a representative on the EPEAT Advisory Council to promote collaboration among stakeholders and aid in the success of the program moving forward. Since 2014 Xerox has committed to launching all new office products with EPEAT® Silver or Gold certification. For example, all new VersaLink and AltaLink products are EPEAT® Silver or Gold as we continue to design our products with the environment in mind. Xerox is the only company to claim all eight EPEAT® corporate optional criteria. Learn more about the EPEAT® program and view current Xerox EPEAT® registered products here.

Reducing Energy Use through Our Products, Technology and Initiatives

- ENERGY STAR®

More than 10 years before the inception of the U.S. EPA ENERGY STAR® Office Equipment program, Xerox introduced the first imaging product with an automatic power-down mode. Since joining with the EPA as a Charter Partner in 1993, we continue to introduce copier, printer, fax and multifunction products that have earned ENERGY STAR® status, even as the certification criteria have grown more stringent.

In 2016, 100 percent of all our new eligible product introductions achieved ENERGY STAR®. This continued success in cutting the power consumption of our laser-based printing products has been achieved by adjustments in the fuser design, changes to the properties of the toner, more efficient electronic controls and the workings of the xerographic system as a whole.

The ENERGY STAR® program, as noted, introduces progressively more stringent requirements over time. The most recent revision went into effect on January 1, 2014. While the standard was challenging to meet, our goal remains to have 100 percent of our new products achieve this label. Xerox and other industry members are working with the EPA to establish the next set of requirements, which will be ENERGY STAR® Imaging Equipment 3.0. Xerox will keep on meeting these new targets in the coming years. These energy requirements serve as the foundation for other eco-labels, such as EPEAT® and Blue Angel, and show our ongoing commitment to reduce product energy consumption.

- Multifunction Devices

Our multifunction systems further reduce the amount of energy required to copy, print, fax and scan by combining the functions of multiple products into one machine. The annual energy savings of replacing several individual ENERGY STAR®-qualified copiers, fax machines and printers with one Xerox ENERGY STAR®-qualified WorkCentre multifunction system is up to 50 percent. Energy savings would be substantially higher if a multifunction system replaces individual products that have not earned the ENERGY STAR® rating.

- Xerox ConnectKey™

Xerox ConnectKey™ is a software solution that enables information to be moved to and from the cloud without the security risks that commonly exist. Cloud computing is an alternative to large data centers and is being recognized worldwide as less energy intensive than data centers while generating fewer GHG emissions. In addition, Xerox ConnectKey™ and Cisco EnergyWise enable energy management by allowing for the control, management and reporting of a device’s power consumption and the setting of power states and timeout intervals.

Deinkability

In recent years, deinkability has become an area of increasing concern, particularly among our Graphic Communications customers. Ensuring that prints produced with our equipment and materials can be responsibly managed at the end of their useful life is an important consideration in our product development process. When appropriate, independent testing confirms that these prints pose no unique challenges to the recycling stream. While the deinkability of xerographic prints has long been demonstrated, a key milestone for a new technology came in 2010 when our CiPress printer achieved a “Good Deinkability” rating from INGEDE, the international association of the deinking industry.

Packaging and Distribution

Packaging and distribution are integral parts of our product commercialization process. We strive to eliminate, reduce, reuse and recycle packaging and eliminate the use. We also require packaging suppliers to comply with bans and restrictions for a variety of chemicals. We document our expectations in our Environment Health and Safety Requirements for Packaging Standard — EHS-710, and our General Packaging Standard — 88P311. Our commercial equipment is designed and tested extensively to be shipped without any required packaging. Eliminating or reducing packaging wherever feasible, conserves natural resources and decreases fuel use for distribution. Doing so represents a sustainability win for business and the environment.

We also offer the Xerox® Automated Packaging Solution. This system uses the latest in document technology to print, finish and cut customized folding cartons in short runs. By creating packaging quickly and cost effectively, this tool enhances material efficiencies as well as decreases obsolescence through customized boxes and containers. Automated packaging reduces financial and environmental costs associated with warehousing, storage and disposal. It also proves an advantage for focused marketing campaigns and rapidly changing competitive markets.

Learn more about our sustainable packaging. +

A few examples that illustrate our commitment to sustainability in this area:

Developer Housing Assembly — Converting to Use of Molded Pulp

For many years our principal supplier shipped housing assemblies to us packed in foam. We moved production to the U.S. and redesigned the packaging to take advantage of readily recyclable molded pulp solutions.

Expanded polystyrene end caps, weighing 68 grams each and measuring 5 inches in length, 6.5 inches in width and 6 inches in height per side, were replaced with molded pulp end caps. The result was a decrease in our material footprint large enough to increase the amount of product load from 77 units per pallet to 144, a gain of 87 percent. This eliminated 4,800 kilograms (10,575 lbs.) and 8,559 cubic feet of foam annually; it also reduced costs and conserved natural resources.

WorkCentre 7120 Customer Replaceable Units (CRUs) — Reducing our Footprint

As with our developer housing assemblies, we redesigned packaging provided to us by a large supplier of color WorkCentre 7120 CRUs by removing polystyrene end caps and decreasing the size of the package. The result: reduction of 4,725 kilograms (10,417 lbs.) or 27,756 cubic feet of polystyrene waste annually, and 27 percent increase of product per unit load.

Xerox Replacement Cartridges (XRC) — Reducing Solid Waste

For XRC products, Xerox packaging engineers replaced hot wire expanded polystyrene end caps with inflatable air bags. Upon receipt of the package, the air bags are easily deflated, producing far less solid waste by mass and cubic volume compared to polystyrene; and this change is an environmentally preferable alternative.

Third-Party Supplies Sold by Xerox

Xerox sells imaging supplies through its distribution network that are manufactured by other companies for use in other OEM printers. Manufacturing processes combine patented and patent- pending technology, environmental management principles and proven waste prevention manufacturing and recycling processes. We thoroughly review these supplies to ensure compliance with appropriate regulatory requirements. In addition, we assess them against our own stringent standards. The results of these reviews ultimately determine which products carry the Xerox brand. Information is provided on Safety Data Sheets (SDS), which meet the requirements of the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) as implemented through regulations in our various markets.

Striving for a Circular Economy

In the 1980s, Xerox introduced the concept of a circular economy for electronics remanufacturing, long before the term was coined. Our vision was to transform Xerox manufacturing, operations, offices and facilities into waste-free workplaces. We had the same vision for our customer’s workplaces. A world where our electronics and supplies currently in use would be the raw materials of tomorrow at the end of their useful life. Hence, the meaning of the term circular economy. Where quality is not compromised, precious natural resources are conserved and waste becomes an obsolete term. More than three decades later, we are still living the dream and demonstrating that a circular economy approach delivers economic, environmental and societal benefits.

Our aim is to design products, packaging and supplies that make efficient use of resources, minimize waste, reuse material where feasible and recycle what cannot be reused. To meet this commitment, we developed several programs: Xerox Green World Alliance provides a collection and reuse/recycling program for spent imaging supplies; Xerox Product Takeback and Recycling Program manages equipment at end-of-life; and we invest in technologies that reduce the creation of waste. For laser-based products, materials innovation has extended the life of critical replaceable components by up to 50 percent.

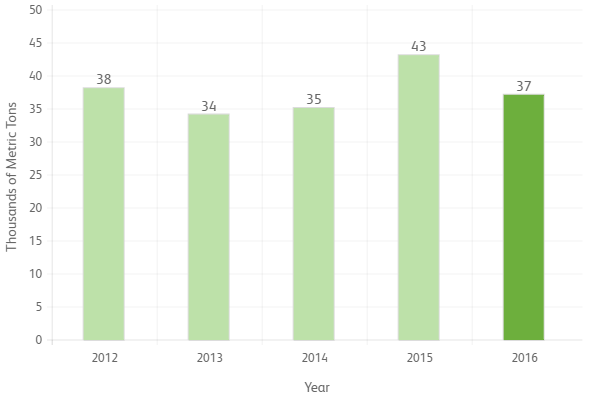

Our approach to managing products at end-of-life translates into significant environmental and financial benefits. Globally, our combined returns programs (equipment resale or remanufacture in conjunction with parts and consumables reuse and recycling) prevented nearly 37,000 metric tons of waste from entering landfills in 2016.

Consumables Takeback and Recycling

Our GWA initiative, as noted, is a collection and reuse/recycling program for customers for their used imaging supplies. GWA is central to our commitment to waste-free products.

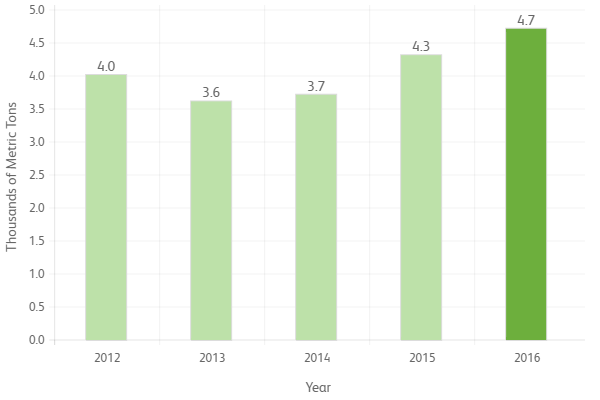

Currently, more than 35 countries participate in the Xerox GWA. Each has its own GWA country website that describes the processes available to the customer or the appropriate points of contact for more information. Worldwide, our customers returned more than 4.2 million cartridges, toner containers and other used supply items in 2016, equating to 4,800 metric tons.

Returned products are sorted, and items suitable for remanufacturing are cleaned, inspected and then remanufactured. Remanufactured consumables, containing an average of 90 percent reused/recycled parts, are built and tested to the same performance specifications as new products. Items that are not suitable for remanufacturing are recycled or recovered through energy from waste. Recycled waste toner and toner reclaimed from manufacturing that qualifies for reuse may account for 25 percent of the weight of new toner, without compromising toner functionality. Reusing waste/reclaimed toner saves several million dollars in raw material costs each year. Of the toner that cannot be reclaimed, 75 percent is recycled by our consumables recycling partner while the remaining volume is utilized at energy from waste facilities to generate steam and electricity.

Total Waste Diverted from Landfills from Returned Cartridges, Bottles and Waste Toner

Equipment and Parts Takeback and Recycling

In the early 1990s, we pioneered the practice of converting end-of-life electronic equipment into products and parts that contain reused parts while meeting new-product specifications for quality and performance. We have developed a comprehensive system for taking back end-of-life products, which processes assets through remanufacture, refurbish, parts reuse, recycling or broker sales, each of which fully supports our waste-free initiatives.

We design our machines with high durability and reuse capability in order to facilitate multiple product lifecycles. During the active phase of a product, all returned equipment and spare parts are evaluated for reuse opportunities throughout the supply chain. Finally, all parts and equipment that are not destined for re-use have specific guidelines, which facilitate easy and consistent recycling.

Learn more about how we enable reuse. +

Xerox enables reuse according to the following principles:

- Reuse of complete end item - This approach requires the least reprocessing, transportation and energy usage.

- Remanufacturing or conversion into a newer-generation product or part - Product families are designed with a high level of commonality to enable maximum reuse in this manner. This allows us to remanufacture to “as new” performance specifications while reusing 70 to 90 percent of the machine components by weight without degradation of quality or performance.

- Used Equipment - Equipment returns are evaluated for potential re-use. Based on the condition and market demands, equipment may be put through an extended maintenance/verification process to return it to a high standard and then be redeployed. Approximately 56 percent of machines returned in the U.S. are given new life by being sold as used or sent for remanufacturing of some sort.

- Reuse of major modules, subcomponents and parts for spares or manufacturing - Many of our machines that have outlived their useful life are stripped of usable parts and components prior to the scrap/reclaim process. Used spare parts returned from the field also are included in this reuse stream. Xerox continually has been increasing the number of components that are reused in upstream and downstream processes after the original machine has been designated for recycling.

- Material recycling - After the processes noted above have been followed, any remaining portion of a machine is stripped of any recyclable material (e.g., plastics, copper wire) and material requiring special disposal services, such as printed wire boards, batteries and lamps. The remainder of the machine is then sent to an industrial reclaim facility.

- Post-consumer recycled plastic content - All Xerox products contain between 0%-5% post-consumer recycled plastic content.

Changes in volumes of waste diverted from landfills are due in part to increases in product and part re-use opportunities, modifications in product mix, a move to lighter-weight machines as well as growth of regulatory-driven local recycling schemes. For example, the transition to digital equipment and lighter-weight parts has reduced the weight of both office and production equipment by as much as 50 percent over the last 10 years. The decline also includes a decrease in the number of office machines returned for remanufacturing in Europe due to participation in European Union member state Waste Electrical and Electronic Equipment (WEEE) programs. In geographies where Xerox exercises direct control over the end-of-life management of equipment, return rates are high. For example, approximately 57 percent of all U.S. equipment installs are ultimately returned to Xerox for end-of-life disposition, a figure that rises to 100 percent for leased equipment.

In 2016, 11,000 metric tons of equipment and parts related waste were diverted from landfills to recycling at our U.S. Reverse Logistics Center. Globally, that volume rises to 37,000 metric tons.

Total Waste Diverted from Landfills from Returned Equipment and Parts

E-Waste

While Xerox has long been committed to responsible end-of-life management of equipment, the proliferation of e-waste regulations has created a need for multiple programs in different countries and even states. The subtle differences in requirements among these regulations pose challenges from a process consistency and efficiency standpoint. For example, with the implementation of the European Union’s WEEE Directive, we continue to operate our European takeback program to enable equipment remanufacturing and parts reuse. We also participate, as needed, in European member states’ individual collection and recycling programs.

In the U.S., Xerox recently partnered with a large electronics recycler to ensure that our customers have a means for their old imaging devices to be processed in a responsible manner. The program is consistent with the requirements defined in the various manufacturer takeback initiatives.

We carefully manage suppliers that provide recycling and waste disposal services. A waste vendor approval process assesses the safety and environmental practices as well as compliance history of each vendor. Where appropriate, we require these companies to document the final disposition of materials sent to their facilities, including electronic scrap. Xerox does not allow its vendors to send electronic scrap to developing nations for processing. We strive to work with only those recyclers that have implemented voluntary programs certified by accredited organizations. The programs are U.S. EPA’s Responsible Recyclers (R2) or the Basal Action Network’s e-Stewards standards. In addition, in 2014, Xerox’s two U.S. equipment processing facilities achieved R2 certification.

Paper

We recognize our obligation to responsibly source paper and enable efficient paper use. Our strategy begins upstream with the fiber source and continues to processing and manufacturing, through use and end-of-life. We utilize a multi-pronged approach through partnerships with our customers and suppliers, The Nature Conservancy and other stakeholders, including non-government organizations (NGOs), government agencies and academia. Our long-term goal is to support a sustainable paper cycle and minimize environmental impacts while meeting our customers’ exacting business needs.

In 2013, Domtar signed an agreement with Xerox for the acquisition of the Xerox paper and media products business in the U.S. and Canada. This deal gives Domtar exclusive rights for the marketing and distribution of Xerox brand paper and print media. Read more about Domtar and sustainability. The same year Xerox’s paper business in Western Europe was sold to Antalis. Read more about Antalis’s sustainability charter.

Xerox maintains the paper business in its Developing Market Operations. We apply stringent paper sourcing guidelines for companies that provide paper to Xerox for resale. The requirements cover all aspects of papermaking, from forest management to production of finished goods. We supply papers that comply with sustainable forest management standards, including Forest Stewardship Council (FSC) and Program for the Endorsement of Forest Certification (PEFC). FSC-certified papers use raw materials from an FSC-certified source, controlled wood sources or post-consumer reclaimed sources.

Our Partnership with The Nature Conservancy (TNC)

Since 2006, Xerox and TNC have partnered to preserve and protect globally important forests. This work is funded through The Xerox Foundation grants of more than $2 million.

During the third term of the partnership in 2016, Xerox supported the Conservancy’s efforts to:

- Develop and test a broadly applicable carbon methodology for improved forest management that would allow landowners to achieve forest certification and serve as a platform for potential carbon benefits.

- Strengthen a key tool for identifying priority habitats — the High Conservation Value (HCV) approach — for building consistency across projects, disseminating standards and training assessors through global and regional HCV networks. .

- Promote responsible forestry through the implementation of forest management standards by working with Xerox suppliers and other land managers at two sites in North America: Central-Western New York and across the Canadian boreal forest (including a focused project in Northwest Ontario).

These initiatives have improved forest conservation, helping to develop a sustainable paper cycle and advance sound forest management practices through market incentives, landowner investment and resource networks. Most importantly, our work has and will continue to stem the tide of forest loss and degradation, a contributor to global GHG emissions.